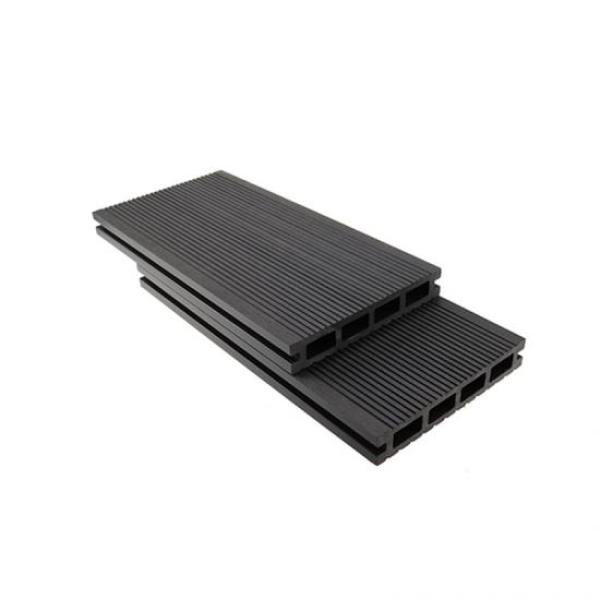

Good choice-Senrui wood plastic composite decking

Composite lumber is a material that is a mixture of wood fiber, plastic (high-density polyethylene (HDPE)) and some type of additive. These ingredients are put together to form a material that is denser, stronger, and heavier than wood alone, a wood-plastic composite.

Due to environmental and durability concerns, composite decking (a mixture of two materials, typically wood pulp and recycled material such as polypropylene or virgin plastic) have appeared on the market. Proponents of composite decking have touted this as a much needed development as this helps to curb logging of trees for new decks.

However composite decking has been found to contain harmful chemicals, cannot be refurbished, and despite claims from decking companies, some composite decking still attracts mold. However newer more modern wood composites feature a cap or shell that prevents mold.

Working with composite lumber is similar to working with wood. However, composite lumber has the added benefit of being less likely to split or delaminate. Some composite lumber is also engineered to be lighter weight for easier handling. Composite lumber is also more stain, scratch, and mold resistant, and is therefore supposed to have a longer life than wood lumber.

Advantages of wood composite decking

Composite lumber comes from the manufacturer as a finished product. There is no need to stain, sand, or paint the material. Composite materials usually cost more than lumber, but their long life and low-maintenance requirements could make them more economical in the long run. Many composites are often made partially out of recycled plastics and waste wood, such as Senrui Wpc Decking, which makes them an environmentally friendly, efficient use of resources

Environmental impact

The growth of wood-alternative products continues to fuel a debate about their environmental value when compared to wood, treated wood, metal and other alternatives. Many suggest that wood decking is made from a more sustainable ingredient and that it carries a smaller manufacturing carbon footprint. Others have claimed that the sawing of wood-alternative products during construction creates dust that will not biodegrade and that the wood-alternative deck boards, when they have outlived their useful lives, will not biodegrade in landfills.

Brief introduction of our factory:

About us:

Factory sizes:40000 square meters

Production line : 23

Number of workers (office:20, workshop:70, R&D: 4 , QC:6)

Since 2009 begin WPC business

Major market for WPC: North America, Western Europe, east Asia.

We provide:

For now, we mainly produce two types of products (indoor flooring and outdoor decking).

Outdoor decking:

1.WPC decking (Hollow Decking Board and Solid Decking Board )

2.WPC Online embossing decking

3.WPC DIY tile

4. CO-extrusion WPC decking

Indoor flooring:

SPC flooring,This is our new product, starting from last year.This is a new kind of environment-friendly material.

We have ten patterns for customers to choose from.

Any question,please feel free to contact us.Email:[email protected]

English

English Japanese

Japanese Spanish

Spanish German

German Russian

Russian Arabic

Arabic Portuguese

Portuguese French

French Korean

Korean Thai

Thai