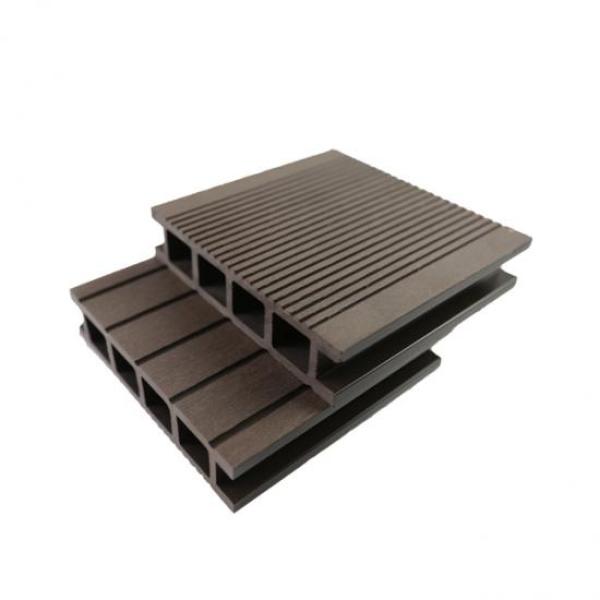

SPC Flooring Installation Guide

Preparations

- The surface of the floor must be clean, dry, and stable.

- Any polish, dirt, paint, etc must be removed from the job surface.

- The floor surface must be flat and leveled with a scraper and putty knife.

- Maintain the room temperature above 59°F (15°C) before installation.

Site Condition

- a.Existing floor surface level must be within acceptable level with a tolerance of

+/- 1mm only; Uneven floors should be made Level prior to installation. Ex. Applying a layer of self-leveling cement over existing surface. Once cured, measure the level again to ensure the surface is ready for installation.

a.Uneven surfaces will cause a high-low variation between SPC planks and a waviness effect after completion.

- b.Uneven walls result in gaps between SPC planks and wall. Optionally skim coat the gaps or skirt the walls with baseboard/ floor trim to give the room a finished look

- c.Check that the doors will still be able to open and close after the floor has been installed (minimum + 3/8” (1 cm). Trim door and door frame as necessary (see step 8)

Installation

- Ensure all products for the installation are from the same lot numbers.

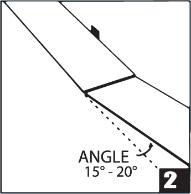

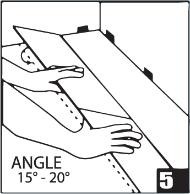

- Position the plank to be installed at the angle of 15° to 20° to the plank already installed.

- Move the plank gently up and down and at the same time exert forward pressure.

- The planks will automatically click into place.

- You can either insert the tongue into the groove, or the groove into the tongue.

- The tongue in groove method is the most common and easiest way. Please refer to the installation diagrams for more details

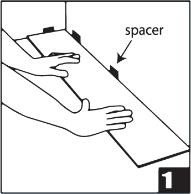

Start at a corner.

Place first plank with tongue side facing wall

Use spacers to maintain an expansion space of 2-3mm between wall and flooring

Insert 2nd plank’s end tongue to 1st plank’s end groove at An angle of 15° to 20°.The plank will click into place when lowered.

Line up edges carefully.

Planks should be flat to the floor

For the last plank of a row, flip a full plank to its under side and place beside the row.

Measure and mark the required length ( remember expansion gap)

Use a ruler and utility knife to score the plank and snap off. Insert as previous diagram.

Begin next row with the last cut off piece from the previous row to stagger the pattern.

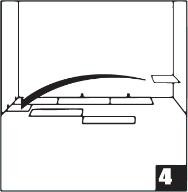

To start second row, assemble your entire row on the subfloor before attaching it to the first row.

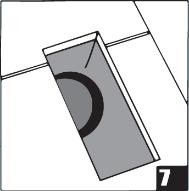

To attach, tilt and push the side tongue into the side groove of the first row at an angle of 15° to 20°.

Lower and click into place lining the edges up carefully. Continue laying remaining planks in this matter.

To fit the final row lay a plank upside down on the flooring as per diagram with the tongue side close to the wall.

Take another plank and place it right on top of the previous row and use it as a ruler. Don’t forget to allow room for spacer. Cut the plank and attach into position.

Heating vents require expansion room.

First, cut plank to the correct length. Place the cut plank at its actual position and use a ruler to measure the areas to be cut out and mark them. Cut out the marked points allowing the necessary expansion distance

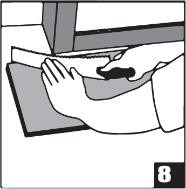

The gap between the bottom of a door and the SPC flooring should be 1 cm height to trim door frames, turn a plank upside down. Place it next to the door frame as per diagram. Use a handsaw and cut away the necessary height so that the planks can slide easily underneath the frame.

English

English Deutsch

Deutsch Français

Français Español

Español Português

Português Русский

Русский عربي

عربي 日本語

日本語 한국인

한국인 แบบไทย

แบบไทย